By Clarrie Snell

The pens may initially take a while to make, however the finished article is extremely durable with brilliant colours that are striking and pleasing to the eye.

Mixing Equipment

- 4 flexible plastic containers (bottom half of small round drink containers or drink cups).

- 6 Stirrers (old hacksaw blades, or wooden sticks).

- Eye dropper.

- Dessert spoon or measuring cup.

Safety

- Wear eye protection during the mixing procedure. The Resin Hardener, MEKP, is a dangerous substance to handle. Safety goggles should be worn during handling, as loss of eyesight is possible if MEKP comes in contact with the eyes.

- Read safety instructions before using this substance.

- Wear face masks with filters to suit chemicals during the mixing procedure, machining and finishing.

- Wear disposable gloves during mixing procedure.

Chemicals

- Acetone for cleaning purposes.

- Surf Board Resin (Finishing Resin GC3).

- Resin Hardener (MEKP)

- Resin colours to suit your taste.

- Vaseline (petroleum Jelly).

Mould and release equipment

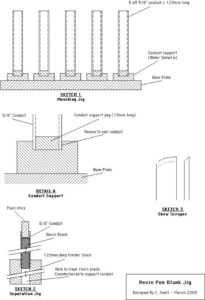

- 5 pieces 5/8 OD electrical conduit x 120mm long.

- Timber moulding jig, to support conduits (see sketch 1).

- Timber separation jig with metal drift (see sketch 2

Preparation

- Place small amount of Vaseline onto moulding jig timber pegs and conduit supports.

- Locate conduits onto timber pegs.

Mixing Procedure

- Place 1 dessertspoon of resin into 3 plastic containers.

- Using 3 separate hacksaw blades, place a small amount of each colour into each of the 3 containers and stir thoroughly.

- Place 9 dessert spoons of resin into the remaining small plastic container .

- With another hacksaw blade, add white colour, slightly more quantity than for the smaller containers and stir thoroughly

- Add 4 drops of MEKP Hardener to each of the 3 colour containers,. Stir thoroughly.

- Add 36 drops of MEKP Hardener to the white colour container and stir thoroughly.

- Pour the contents of the three-colour containers into the white colour container, one at a time, using a circular motion onto the surface of the white resin. DO NOT STIR COLOURS TOGETHER otherwise you will have one solid colour mix and not a colour pattern that you are trying to achieve.

- With a clean hacksaw blade, gently pierce or push the colours into the white colour, just a few times, the more you pierce the more you mix the colours into the white base colour.

- Gently pour mixture into conduits.

- Curing of resin pen blanks may take about 4 hours, depending on temperature. Resin blanks will not stick to the conduits but will shrink away from the sides making it easy to push the blanks out of the conduits.

- After the blanks have cured, support conduit in separation jig. Use a steel drift to remove resin blank from conduit, (sketch 2).

Machining

- Cut resin blanks to 52mm long.

- Set lathe speed to approximately 1200rpm for drilling, turning and finishing operations.

- Place Jacob chuck into headstock and place half resin blank into chuck with about 20mm protruding.

- Drill through with 6.9mm drill, clearing drill regularly to prevent resin blank from overheating. Note 7.0mm drill will drill oversize hole for the pen brass sleeve.

- Repeat above step for other half of resin blank.

- Glue brass sleeves into pen blanks, preferably with a 2 pack epoxy glue.

- After glue has dried, face ends of resin blanks to suit length of pen brass sleeve.

- Place pen blanks onto mandrel.

- Rough turning/shaping may be carried out using a one-sided curved skew scraper, (see sketch 3), or by using 80 grit paper.

- Turn pen to desired shape with pen clip end turned to 8.1 diameter.

Finishing

- Use 240 wet and dry paper with water to remove all marks and imperfections.

- Repeat above step using 400 wet and dry paper and water.

- Finish polish using metal or car polish.

- Repeat above step. The pen should now have a high gloss finish, if not repeat step 3.

- Assemble pen.